Optimizing Spatula Design for Durability Using Fatigue & Thermal Analysis in SolidWorks

Problem Statement

A consumer product manufacturer approached us to evaluate the durability and material performance of a newly designed kitchen spatula. While the product had passed initial structural checks, the client was concerned about long-term performance—specifically, whether the spatula could withstand repeated mechanical and thermal stress without failure over its expected lifecycle. The goal was to validate the design and identify any early failure risks before going into mass production.

Our Engineering Solution

Using SolidWorks Simulation Professional, we conducted a multi-step simulation workflow combining static stress, thermal, and fatigue analysis to evaluate the spatula’s real-world performance. The study was designed to:

Analyze the mechanical response under single-use loading conditions.

Simulate temperature gradients from contact with hot cookware and their effect on material expansion.

Conduct a fatigue life prediction by combining cyclic thermal and mechanical loads using variable amplitude loading.

How We Approached the Problem

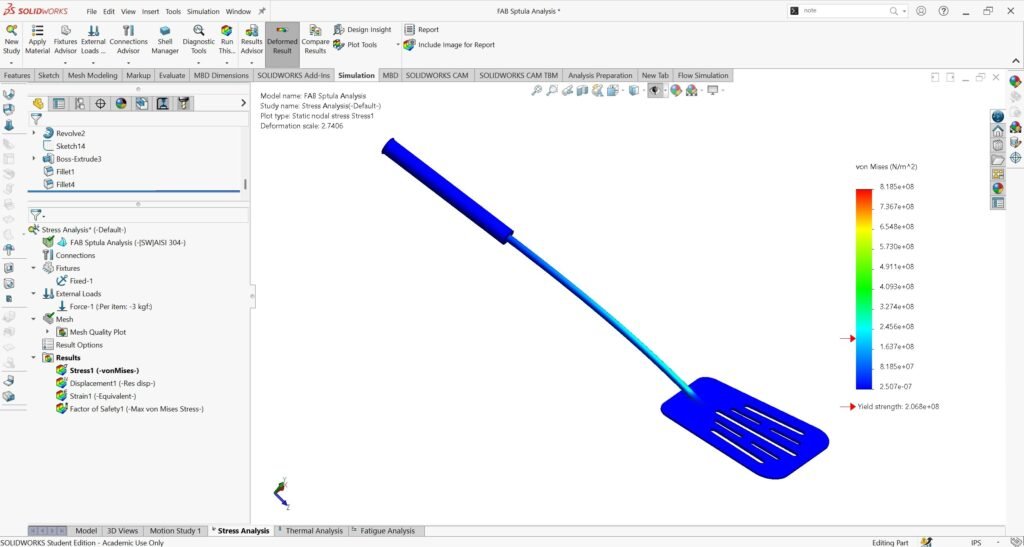

1. Static Stress Analysis – Establishing Baseline Strength

We started with a static structural study to simulate a typical load case—a user applying force while flipping food. The spatula showed a factor of safety of 2.8, indicating it was structurally sound for one-time use without bending or breaking.

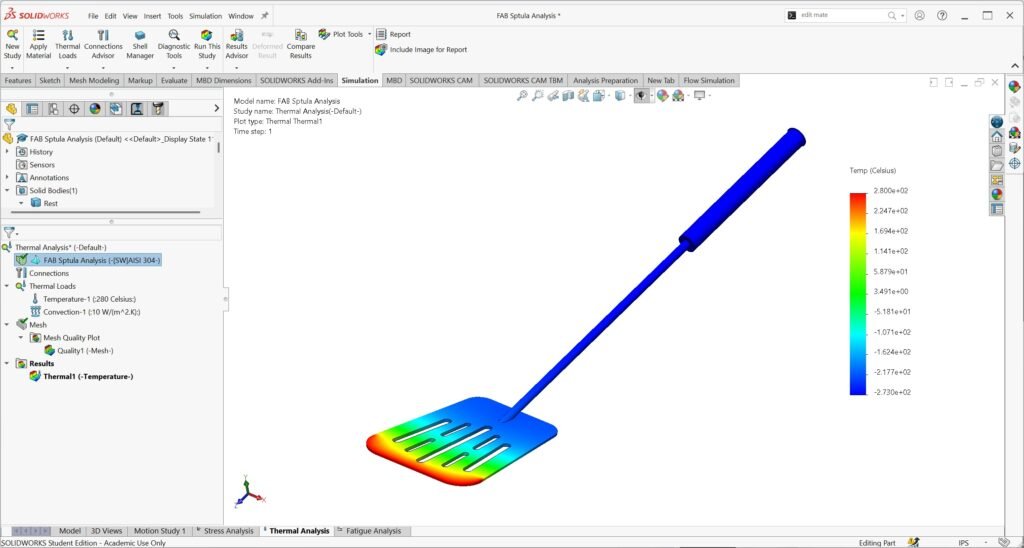

2. Thermal Simulation – Capturing Realistic Temperature Effects

The spatula is often exposed to heat when resting on hot pans. We ran a thermal study to understand how temperature gradients induce internal stresses via expansion. These thermal stresses were extracted and imported into the fatigue study for combined evaluation.

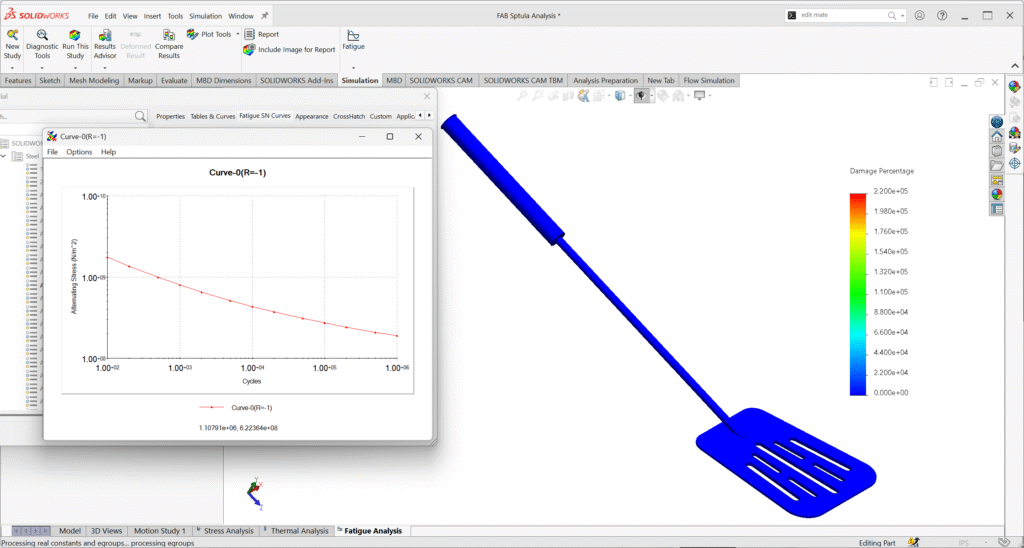

3. Fatigue Analysis – Predicting Life Under Cyclic Loads

Using the fatigue module, we evaluated how the spatula would behave over repeated use. Key considerations included:

Variable amplitude loading (e.g., high-frequency mechanical flexing + low-frequency thermal cycling).

Material fatigue properties via S-N (stress-life) curves.

Load assumptions: both simultaneous and independent event scenarios.

Application of mean stress corrections and selection of appropriate stress values.

The fatigue damage plot revealed that the spatula design consumed only 31% of its expected fatigue life under typical use conditions—a safe margin ensuring product durability over its service period.

Key Results & Client Benefits

Increased Product Confidence

The fatigue study verified that the spatula could survive thousands of cycles of real-life use, improving the client’s confidence in the product’s warranty and reliability.

Cost Savings

-

Avoided over-engineering, allowing for material optimization and cost-effective manufacturing.

-

Reduced risk of early product failure, minimizing potential returns and brand damage.

Design Optimization Support

The simulation provided insight into how changes in material selection or geometry could further enhance performance, allowing the client to make data-driven design improvements.

Warranty & Compliance Readiness

The analysis supported the client’s warranty planning and certification documentation, strengthening their case with retailers and regulatory bodies.

Conclusion

Through our advanced simulation services, we helped the client ensure their spatula design could withstand real-world usage without failure. By combining mechanical, thermal, and fatigue analysis, we provided actionable insights that led to better design decisions, cost efficiency, and improved product reliability.

Whether you’re developing consumer products or industrial components, we can help you validate performance before it hits the market.

Contact us to learn how simulation-driven engineering can elevate your product development.