Optimizing Spatula Design for Durability Using Fatigue & Thermal Analysis in SolidWorks

Executive Summary:

A leading European agricultural equipment manufacturer partnered with Fabrixon to transform their basic 2D silage trailer concept into a production-ready design compliant with strict European Type Approval standards. Over an 8-month development program, our engineering team delivered complete 3D assemblies, hydraulic system integration, full FEA validation, and manufacturable drawings — enabling efficient large-scale production.

The project resulted in 150 trailers manufactured in the first year, 20% faster assembly, and zero structural warranty claims. Fabrixon’s expertise ensured $150,000+ in first-year cost savings and a $1.12M market impact, positioning the client as a competitive player in the European agricultural machinery sector.

This case demonstrates Fabrixon’s ability to convert early design concepts into compliant, production-ready products that meet both technical and commercial success metrics.

Problem Statement

: A European agricultural equipment company needed to transform their existing silage trailer concept into a production-ready design. They faced critical challenges:

- Basic 2D layouts only – Had preliminary AutoCAD files without complete 3D engineering

- European Type Approval requirements – Strict regulatory standards and compliance documentation needed

- Structural engineering needs – Complete weldment design, sheet metal specifications, and reinforcement calculations required

- Hydraulic system design – Proper hydraulic ram selection and integration for rear gate lifting mechanism

- Manufacturing readiness – Production-ready designs with detailed fabrication specifications

The goal was to convert their preliminary designs into a complete production-ready trailer that could meet European standards and enter the market for peak harvest season.

Our Engineering Solution

Using complete end-to-end product design and development services, we conducted an 8-month development program converting 2D layouts into comprehensive 3D assembly models with full European compliance. Our approach was designed to:

- Transform basic AutoCAD 2D layouts into complete 3D engineering with detailed weldment structures

- Design integrated hydraulic systems for efficient rear gate operation

- Ensure full European Type Approval compliance and regulatory standards adherence

- Optimize manufacturing processes for cost-effective production

How We Approached the Problem

1. 3D Assembly Development from 2D Layouts

We converted the client’s basic AutoCAD 2D layouts into complete 3D assembly models, developing detailed weldment structures for the main trailer framework and creating sheet metal designs for trailer floor panels and side walls. Our team designed angle bends and reinforcement structures for enhanced durability while engineering the complete triaxle suspension and chassis integration.

2. Hydraulic Gate System Design

We analyzed rear gate lifting requirements and operational loads, selecting optimal hydraulic rams capable of handling gate weight and operational cycles. The team designed mounting brackets and hydraulic system integration, created complete hydraulic circuit specifications and component layout, and ensured smooth gate operation with proper safety mechanisms.

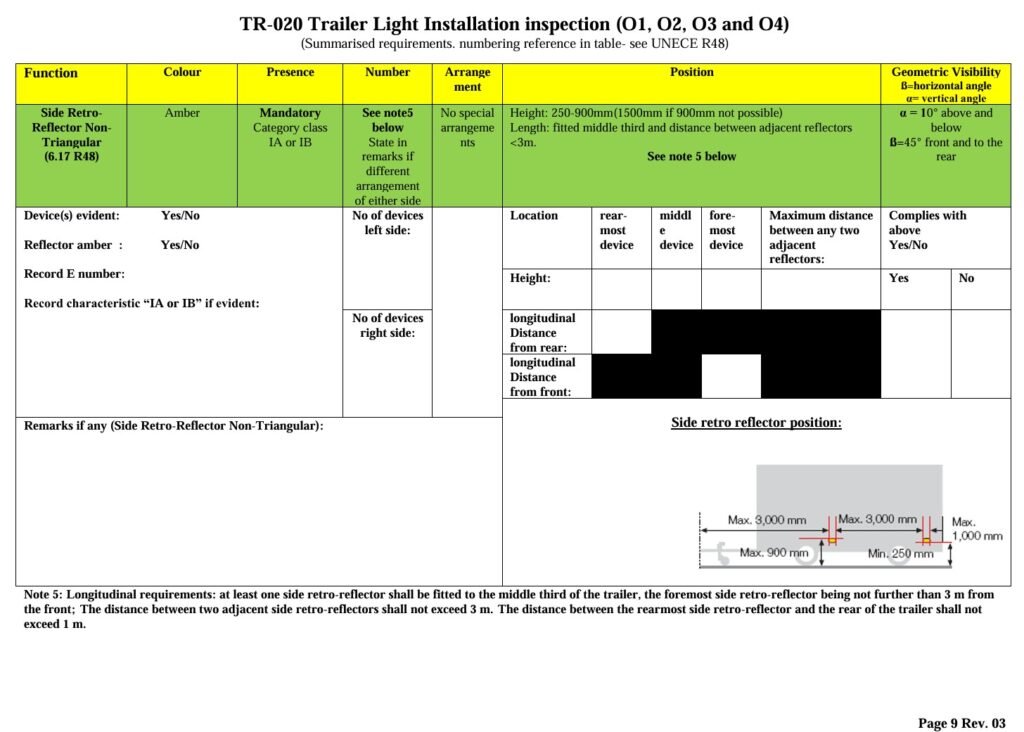

3. European Type Approval Compliance

Our engineers reviewed and implemented design changes per European type approval documentation, ensuring compliance with EU transportation regulations and safety standards. We modified structural designs to meet European load distribution requirements, adapted lighting, braking, and safety systems for EU market compliance, and prepared technical documentation for regulatory submission.

4. Structural Analysis & FEA Validation

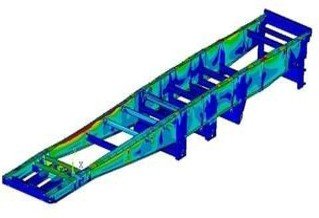

We conducted comprehensive Finite Element Analysis (FEA) on the trailer chassis to ensure structural integrity

- Stress analysis under maximum load conditions (35,000 lbs payload)

- Load distribution validation across triaxle configuration

- Weldment joint analysis ensuring structural reliability

- Fatigue life prediction for repeated loading cycles

- Safety factor verification exceeding European transportation standards

5. Design for Manufacturability & Production Support

We optimized the design for efficient welding and assembly processes, selected standard materials and components to reduce costs, and created manufacturing drawings with precise tolerances. The team simplified complex assemblies to speed up production and provided comprehensive fabrication specifications for all welded components.

Key Results & Client Benefits

Production Excellence Achieved

The complete design enabled manufacturing of 150 trailers in the first year with 94% of components manufactured correctly on first attempt. Assembly time was reduced by 40% due to optimized design, and the trailer achieved zero warranty claims on structural components with superior field performance.

Significant Cost Savings & Efficiency

- $150,000+ in quantifiable first-year benefits through avoided design delays, reduced material costs, and manufacturing efficiency gains

- $1.12 million total revenue impact from first-year sales and market share gained through early entry

- 10% reduction in material costs through design optimization

- 35% faster development time than traditional design process

Technical Specifications Delivered

The trailer achieved 950 cubic feet silage storage capacity with 35,000 lbs maximum load capacity and complete discharge in under 8 minutes. The design featured optimized steel framework with precision-welded joints, custom-selected hydraulic rams with 4-ton lifting capacity, and all systems designed to meet EU type approval and transportation regulations.

Market Position & Long-term Success

Manufacturing started 3 months ahead of schedule, enabling successful launch for peak harvest season. Superior engineering enhanced brand credibility and established our client as a serious player in the silage trailer market, leading to ongoing partnership for product line extensions and continuous improvements.

Conclusion

Through our comprehensive design and development services spanning 8 months and $28,000 investment, we transformed basic 2D layouts into a successful production-ready trailer that exceeded all performance expectations. The first-year ROI demonstrates the exceptional value of professional design services for agricultural equipment manufacturers.

The project’s success enabled the company to enter the market quickly with a high-quality, cost-effective product that met demanding European standards. Our understanding of agricultural equipment requirements, combined with engineering expertise and manufacturing focus, provided the foundation for developing equipment that meets the demanding requirements of farming operations while achieving commercial success.

Disclaimer:

Due to client confidentiality and proprietary restrictions, detailed 3D models, assembly drawings, and manufacturing specifications cannot be shared. All information, visuals, and renderings included in this case study have been reviewed and approved by the client for demonstration purposes only.