CFD Thermal Analysis of a Household Toaster

Executive Summary

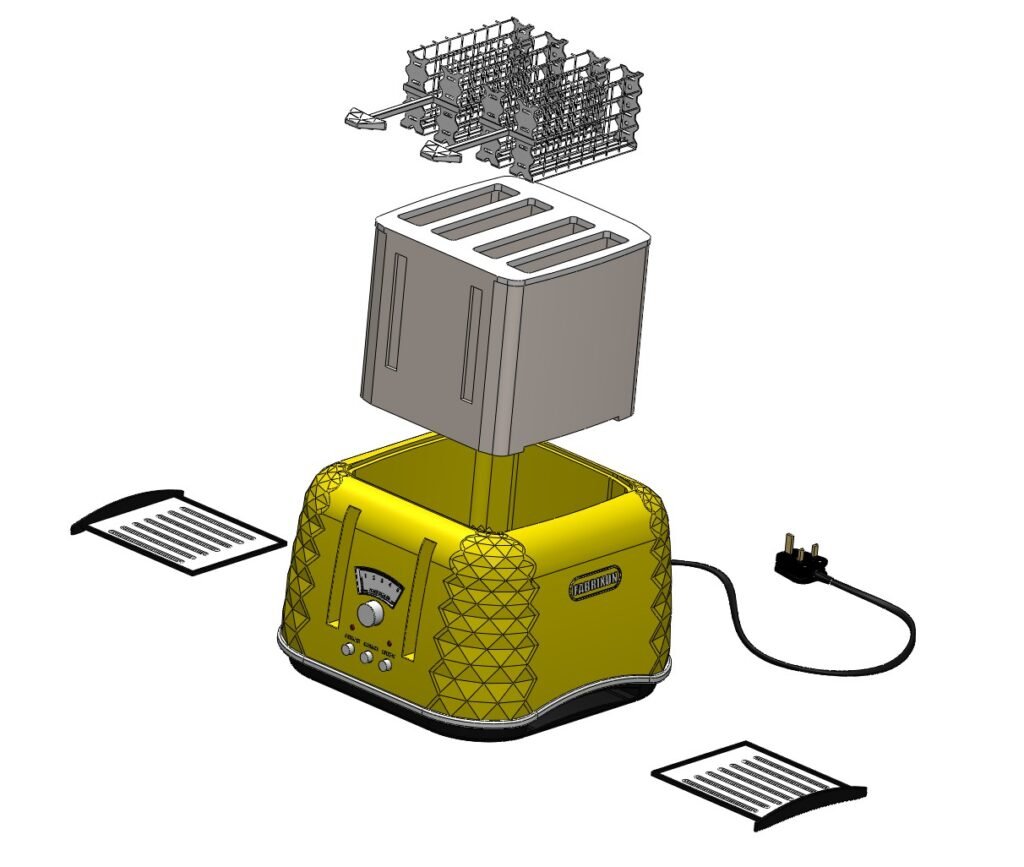

A CFD simulation was conducted on a household toaster assembly to evaluate its thermal performance, airflow behavior, and safety compliance. Using SolidWorks Flow Simulation with conjugate heat transfer (conduction, convection, and radiation), we modeled the heating coils, internal airflow, and thermal structure. Results confirmed the toaster maintains safe operating temperatures while delivering efficient heating performance, validating the design prior to physical prototyping

Problem Statement

The client needed confirmation that their toaster design would:

- Deliver consistent thermal performance across all bread slots

- Ensure heating coils operate within material safety limits

- Maintain external casing temperatures below regulatory touch-temperature thresholds

- Effectively manage both convective and radiative heat transfer

Our Engineering Solution

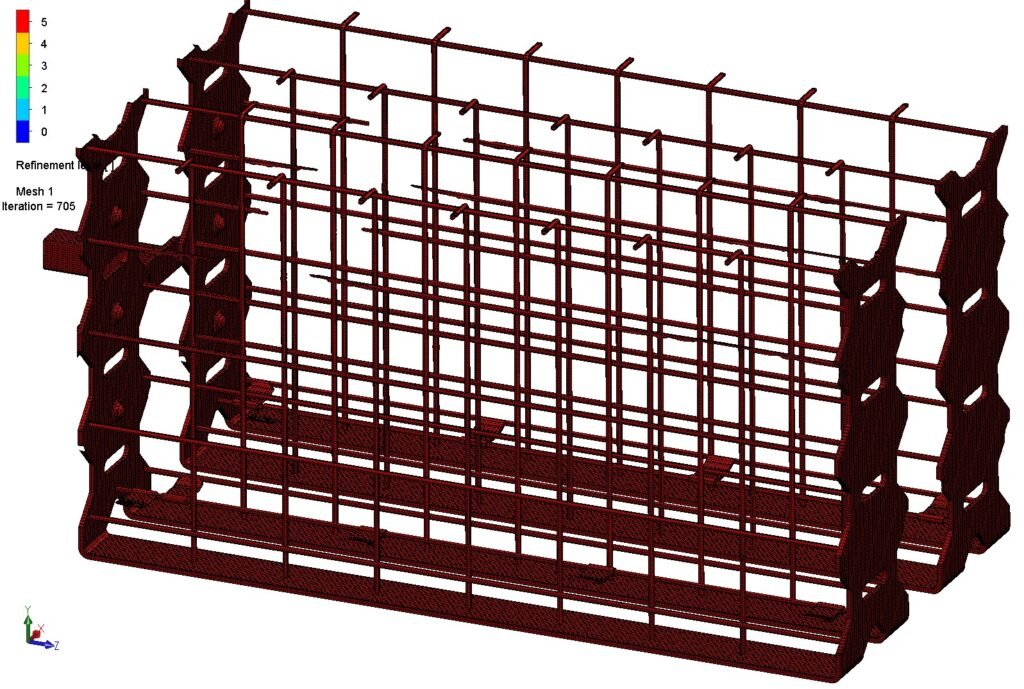

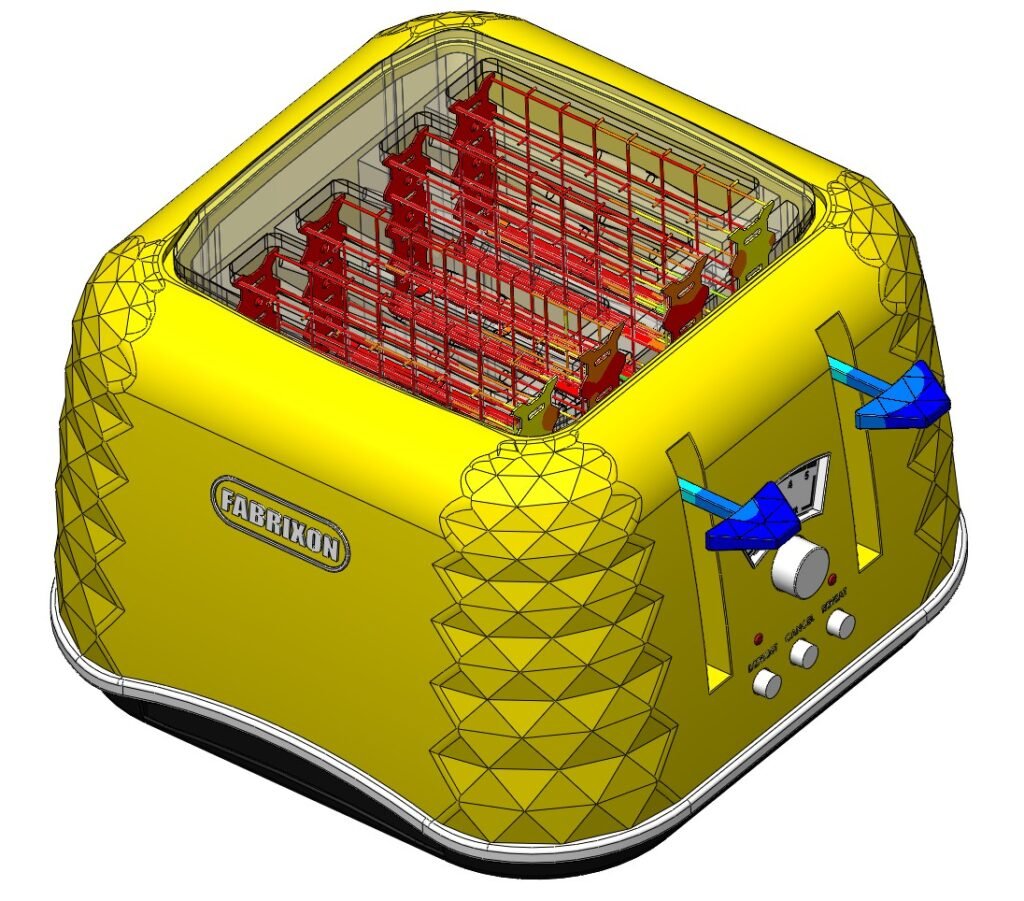

We developed a comprehensive thermal-fluid simulation including:

- Heating Input: 1200W total power distributed across Nichrome heating elements

- Physics Models: Steady-state conjugate heat transfer with surface-to-surface radiation

- Boundary Conditions: Natural convection with 20°C ambient environment

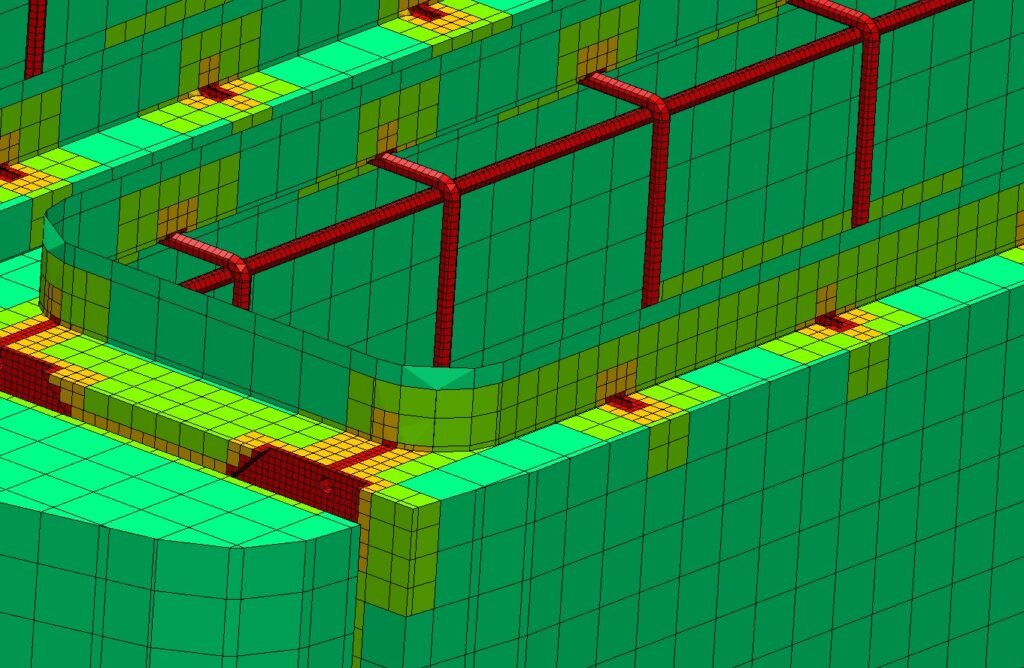

- Mesh Strategy: Local refinements around heating elements and critical surfaces

How We Approached the Problem

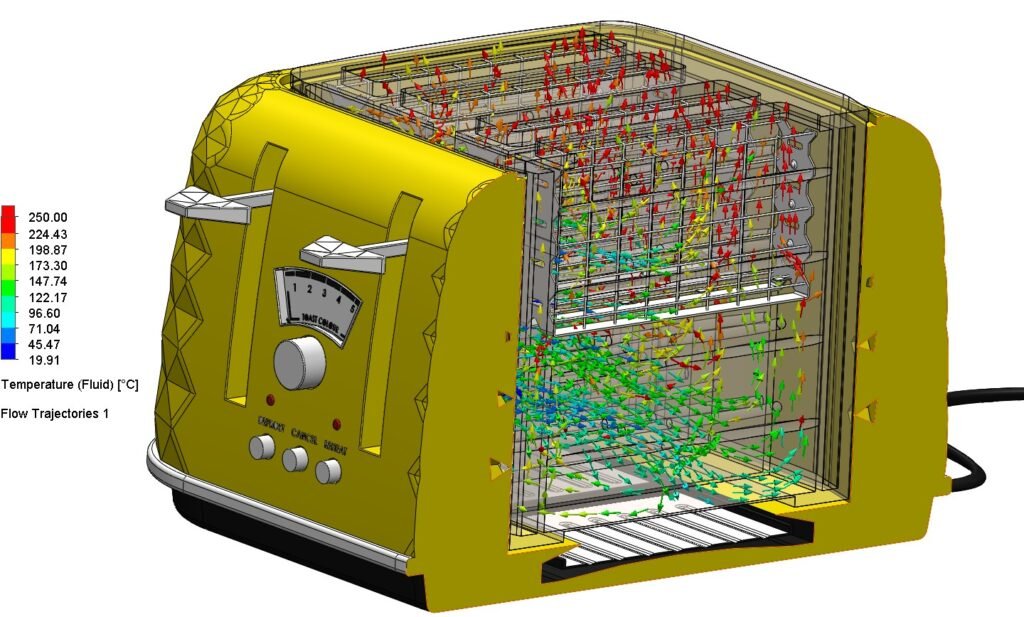

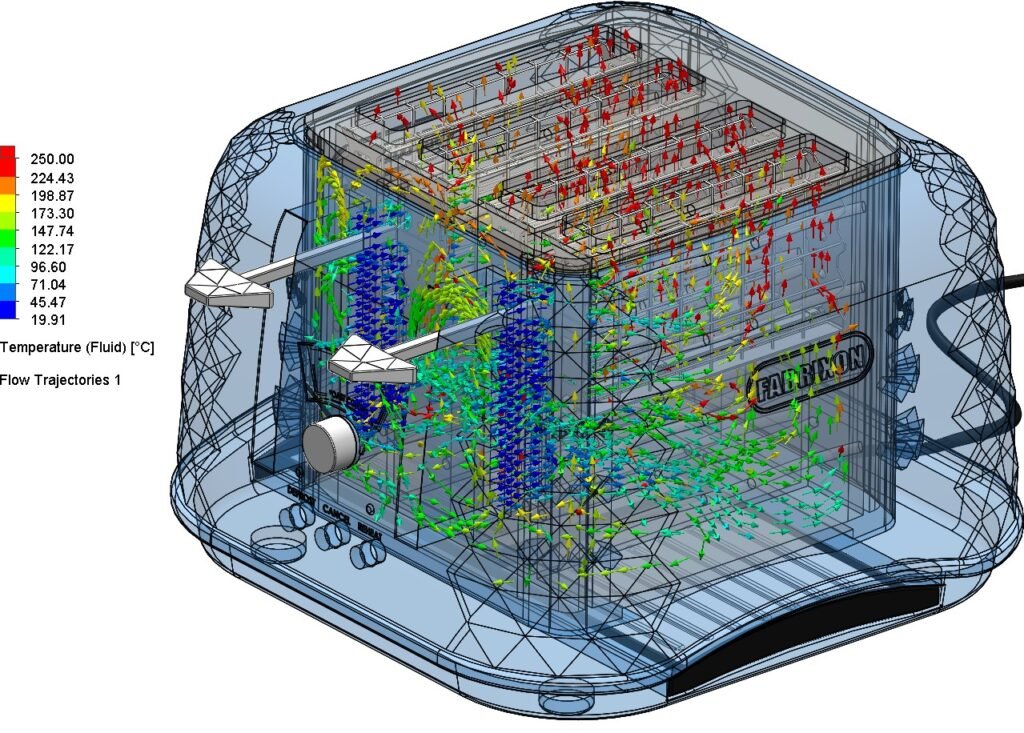

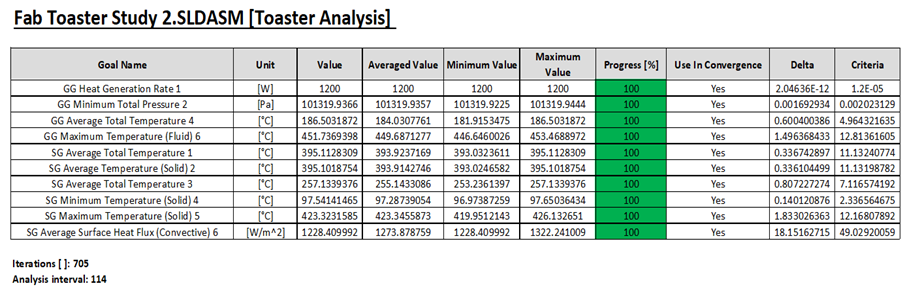

Thermal Performance

- Heating Element Temperature: 423°C maximum (within Nichrome operational limits)

- Internal Air Temperature: 186°C volume-averaged with excellent uniformity (±2.5%)

- Wire Grill Temperature: 257°C average (providing effective toasting surface)

- Heat Transfer Distribution: ~1.2 kW/m² convective flux with significant radiative contribution

Safety Compliance

- External Casing: Maintained below 60°C touch-temperature limit (IEC 60335-1)

- Internal Components: All temperatures within material specifications

- Thermal Management: Effective natural convection prevents hot spots

Airflow Characteristics

- Established natural convection pattern with cold air ingress and hot air egress

- Minimal flow resistance ensures efficient air turnover

Stable recirculation zones promote uniform heating transfer.

Key Results & Client Benefits

- Risk Reduction: Validated thermal safety before prototyping

- Performance Confirmation: Demonstrated efficient heating distribution

- Design Confidence: Verified compliance with appliance safety standards

- Cost Savings: Eliminated multiple prototype iterations

Conclusion

This CFD analysis confirmed the toaster design achieves safe and effective thermal performance under operating conditions. The design maintains component temperatures within safe limits while delivering consistent heating performance.