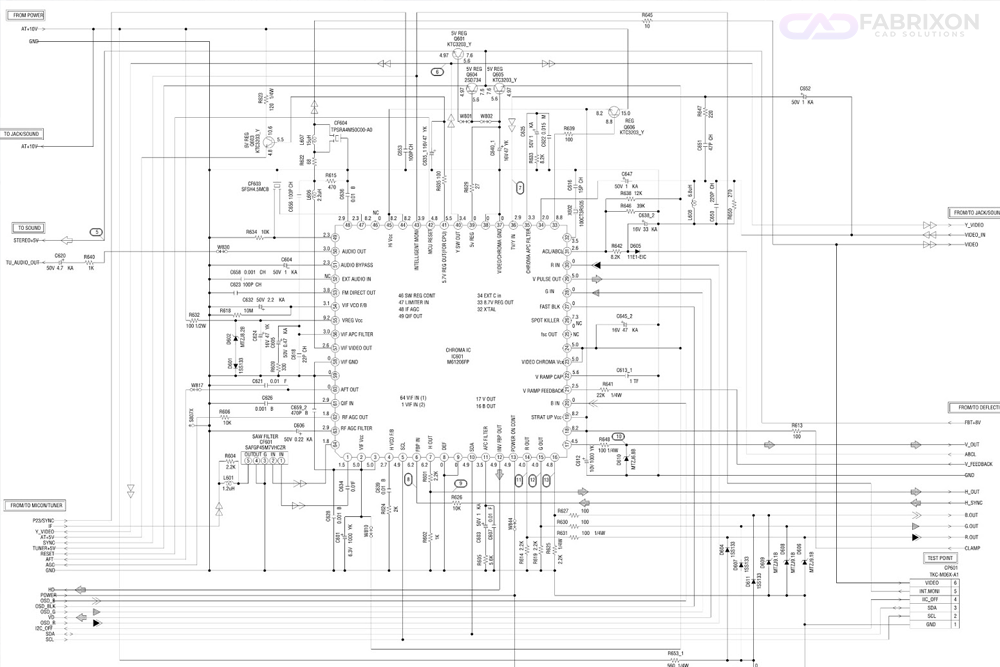

A schematic diagram is a visual representation of an electric circuit, utilizing standard symbols for parts like resistors and capacitors. It drafts logical links, serving as a design for contriving and troubleshooting circuits. Contrary to wiring diagrams, schematic drawings prioritize function over active layout. They are essential for engineers utilizing software like SOLIDWORKS Electrical.

Understanding Schematic Diagrams:

Schematic diagrams simplify circuits into analytical models, displaying parts like inductors and switches. Lines present wires, often marked as nets (e.g., VCC, GND). These diagrams concentrate on functionality, not active position, assuring universal clarity. Familiarity with symbolizations and standards such as IEC is necessary.

Importance of Schematic Diagrams:

Schematics are all-important for designing, gathering, and keeping up circuits efficiently. CAD drawing standards are essential to standardize communication, bringing down faults for technicians and engineers. Multi-line diagrams allow careful links, assisting in troubleshooting. Their clarity assures authentic electro-mechanical assemblies.

Standards for Schematic Symbols:

Schematic symbols stick to standards such as IEC, ANSI, and NEMA for consistency. IEC utilizes rectangles for resistors, although ANSI chooses zig-zags. These measures assure worldwide legibility, vital for multinational projects. Variants exist, just line up with component functionality.

➤ Values and Attributes

Symbols include attributes like resistance (ohms), capacitance (farads), or voltage (5V). These define component functioning, associated with manufacturer part numbers. Attributes dwell in Bills of Materials (BOMs) for procurement. Clear-cut marking keeps fat-finger faults during assembly.

➤ The International System of Units

Schematics utilize SI units, specified as ohms for resistors and volts for power sources. SI assures precision over universal designs, avoiding misunderstanding. Annotations such as “3.3V” or “GND” abide by SI standards. Uniform units are vital for multi-line plots.

Common Schematic Symbols:

Resistors are displayed as zig-zags (ANSI) or rectangles (IEC), capacitors as collateral lines. Polarized capacitors bear an arched plate for the cathode. Inductors look like coils, batteries are switching lines. Switches, like SPST, utilize breaks with actuators.

Creating a Schematic Diagram:

Creating schematics needs putting symbols for components like potentiometers and connecting them. Softwares like Electrical Schematic Designer (ESX) streamline patterns with libraries. Designers assure clarity, sticking to IEC or ANSI standards. The outcome is an operational, clear diagram.

➤ How to Create a Schematic Diagram?

Specify the circuit’s function, choosing components such as BJTs (Emitter, Base, Collector). Utilize a software system to cast symbols and nets, marking attributes like part numbers. Follow-up for abidance with standards like NEMA. Nail down with a title block for project particulars.

➤ Naming the Schematic Nets

Nets, such as VCC or GND, are marked to clear up power or ground links. Green wires oftentimes show ground nets. Consistent naming, admitting wire size, or device ID, helps with troubleshooting. Clear up labels to keep ambiguity in multi-line plots.

➤ Junctions and Nodes

Junctions, displayed as dots, link up multiple nets, like power to a resistor. Nodes, marked with voltages (e.g., 5V), label individual connections. Exact junction notation keeps errors in system interlink diagrams. Lost dots can interrupt circuit interpretation.

Best Practices for Drawing Schematic Diagrams:

Utilize clear layouts, lining up components like capacitors in an order. Abide by signal flow left to right, utilizing uniform symbol sizes. Include title blocks with job number and author. Softwares like SOLIDWORKS PDM assist in dealing with designs, bringing down errors.

Reading and Interpreting Schematic Diagrams:

➤ Schematic Nets

Nets specify links, marked as VCC or ground for clarity. Green wires oftentimes refer to ground nets in schematics. Drawing nets brings out electrical circuit functionality, vital for troubleshooting. Misinterpreting nets can lead to assembly faults.➤ How to Read a PCB Schematic?

PCB schematics map electrical circuits to board layouts, commencing with power nets like 3.3V. Line signal routes, cross-referencing with SOLIDWORKS Electrical 3D layouts. Realize component position, like inductors, for assembly. This assures exact repairs.Advanced Topics in Schematic Diagrams:

Hierarchical schematics and computer simulation heighten complicated designs. System interlink diagrams allow high-level overviews utilizing blocks. Simulation examines circuits virtually, improving dependability. These methods support modern electro-mechanical assemblies.

➤ Schematics for Illustration

Illustrative schematics define circuits, exhibiting fundamental components like batteries. They neglect small details for clarity, which is perfect for teaching. System interlink diagrams utilize blocks for stakeholder demonstrations. These prioritize communication across details.

➤ Schematics for Simulation

Simulation schematics include attributes for software like SPICE. Elaborated models of parts, like rheostats, assure exact analysis. Simulation brings down prototyping costs for complicated circuits. It corroborates designs before building up.

➤ Schematics for Building

Build up schematics, guide assembly, particularization nets, and attributes like wire size. They let in BOMs and exact junction notation for parts like SPDT switches. Clear-cut diagrams, made with ESX, assure exact manufacturing. Technicians trust their techniques for best output.

Conclusion:

Schematic diagrams are all-important for electrical engineering, standardizing electrical circuit design with symbols and nets. Software like SOLIDWORKS Electrical and standards like IEC increase their usefulness. They aim for effective assembly and troubleshooting. Mastery assures authentic, modern circuits.

Frequently Asked Questions(FAQ's)

Q1. What is the primary difference between a schematic diagram and a wiring diagram?

Schematics exhibit orderly connections for components like resistors, concentrating on function. Wiring diagrams portray active wire layouts, directing installation. Schematics aid design; wiring diagrams support assembly.

Q2. How do schematic symbols differ between IEC and ANSI standards?

IEC utilizes rectangles for resistors, and ANSI utilizes zig-zags. IEC prioritizes universal simplicity; ANSI is prevalent in North America. Both assure clarity for parts like capacitors. Standards line up for worldwide understanding.

Q3. Why is it important to include attributes like resistance, capacitance, and voltage in schematic diagrams?

Attributes such as resistance (ohms) assure the right component functioning. They direct BOM creation and procurement. Neglecting them risks faults, like false voltage (5V). Clear attributes heighten circuit dependability.

Q4. How can hierarchical schematics simplify complex circuit designs?

Hierarchical schematics carve up circuits into blocks, like an arrangement of interlink diagrams. Each block, holding components like inductors, betters legibility. They simplify debugging big patterns. This scales for complicated systems.

Q5. What role does simulation play in the schematic design process?

Simulation examines schematics with parts like BJTs virtually. Tools such as SPICE analyze performance, bringing down prototyping costs. Exact attributes assure authentic results. Simulation corroborates patterns before assembly.